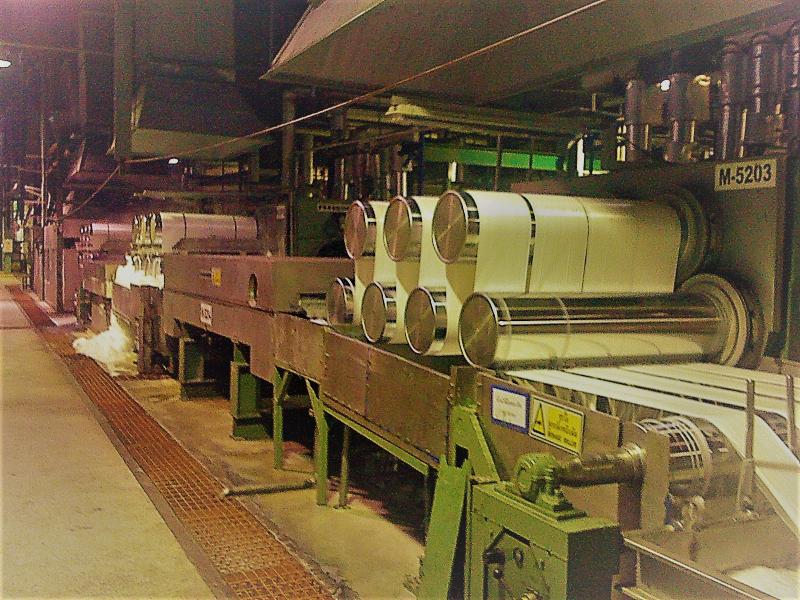

Wire Rod Mills Automation upgrading - SISCO Plant

กลุ่มเหล็ก

ในช่วงกลางเดือนมิถุนายนพ.ศ.2565 VR MASTER ได้รับสัญญาว่าจ้างให้ปรับปรุงระบบควบคุม automation ของโรงงานผลิตเหล็กลวดที่โรงงาน ทาทา สตีล

แมนูแฟคเจอริ่ง (ประเทศไทย) – SISCO ขอบเขตการจัดหาประกอบด้วยตู้ local control ิbox, PLCs พร้อม remote I/O, ระบบ HMI SCADA, การจัดการโครงการ, วิศวกรรมฮาร์ดแวร์, การพัฒนาซอฟแวร์ PLC และ HMI, การติดตั้งและทดสอบระบบ, การฝึกอบรม, และการสนับสนุนการผลิต