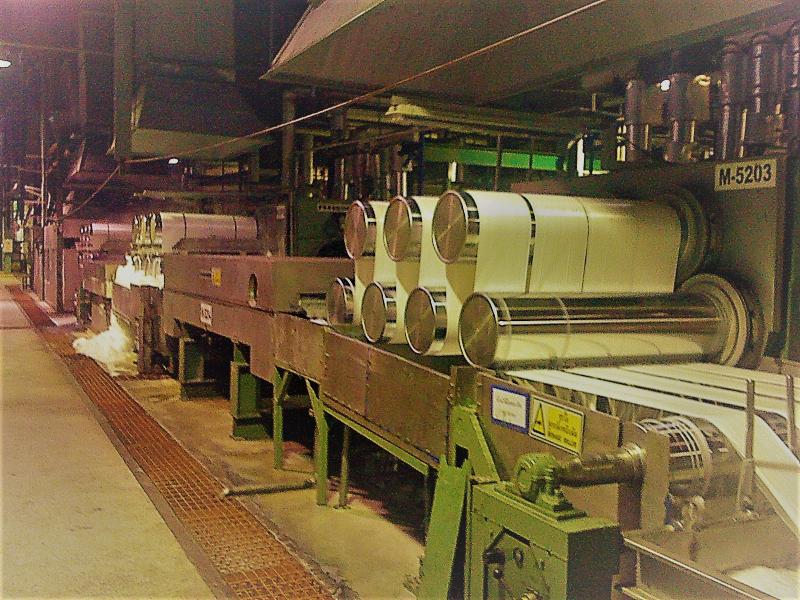

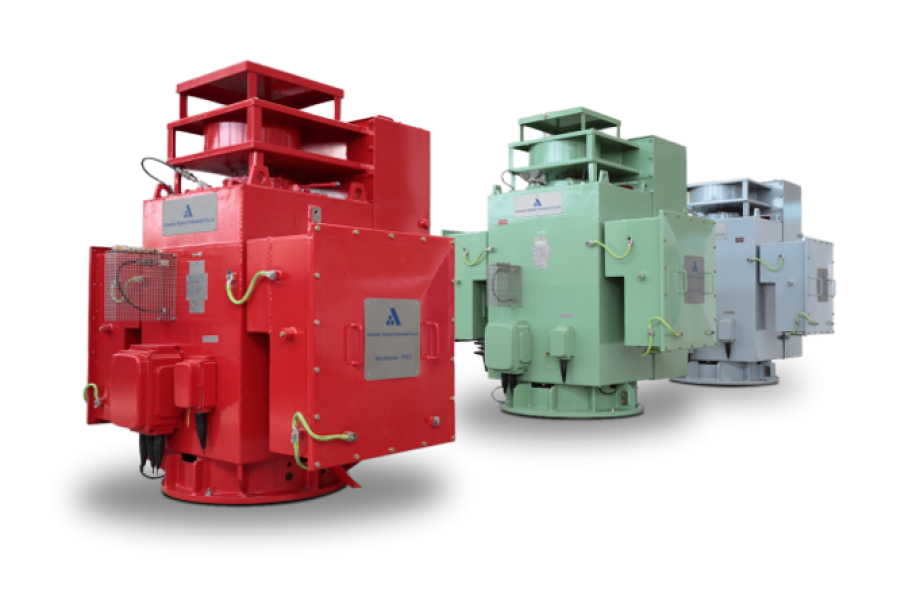

Rod Mills Automation & Drives system Upgrading

เหล็ก

2015 VR MASTER is awarded a 56Million Baht EPC contract for upgrading automation and drives system for Wire Rod Rolling mills at AMSTEEL MILLS, Malaysia