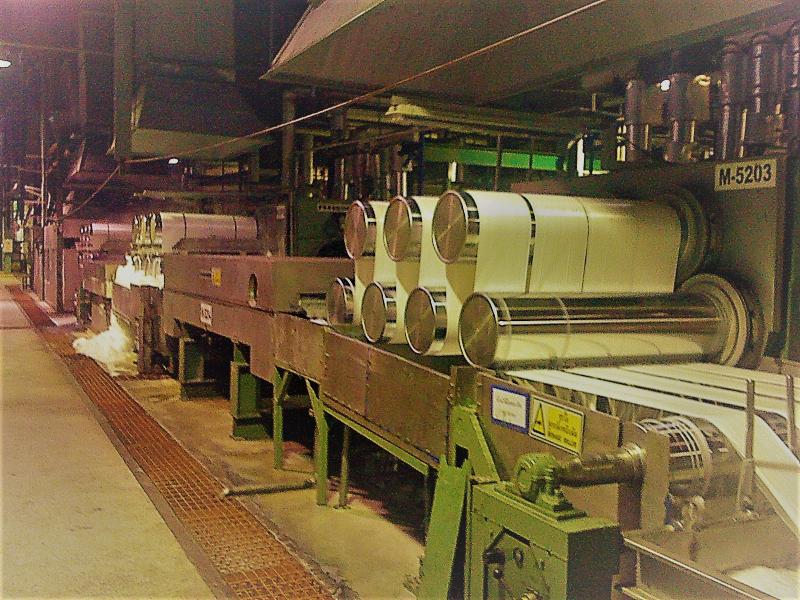

Plate Mill project - Indonesia

กลุ่มเหล็ก

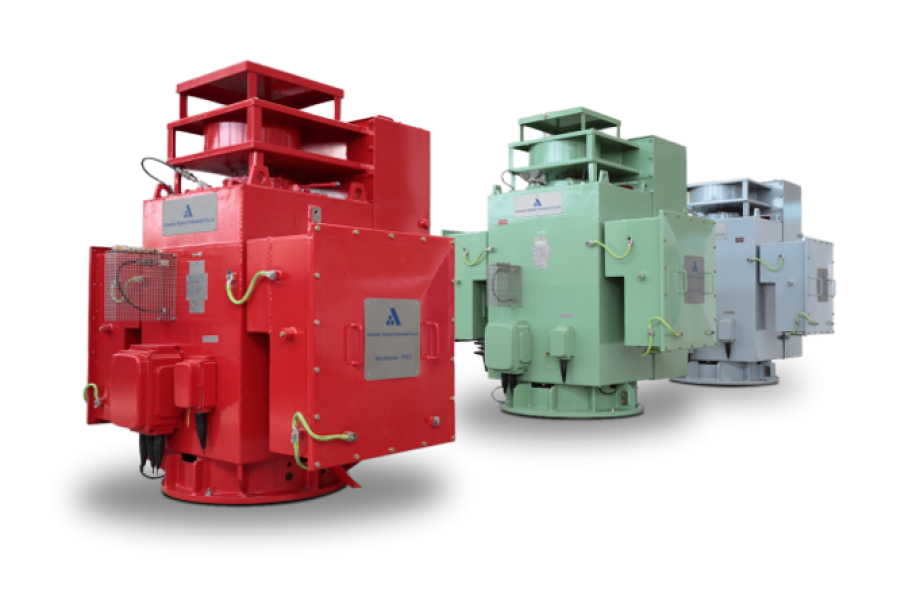

ในปีพ.ศ.2567 บริษัท VR MASTER ได้รับความไว้วางใจจาก กลุ่มบริษัท DELI ประเทศอินโดนีเซีย ให้ดำเนินการจัดหาและส่งมอบระบบไฟฟ้าและระบบขับเคลื่อนแบบครบวงจร สำหรับ Roller Conveyors โครงการ โรงงานรีดแผ่นเหล็ก (Plate Mill) และ โรงบำบัดน้ำ (Water Treatment Plant) แห่งใหม่